Hello users of Lemmings world and welcome to the first edition of…

LAPPLAND’S CHEMICAL SERIES

Today I will show you the process of methamphetamine manufacture.

Please keep in mind that the manufacture of methamphetamine is illegal and so is the sale and consumption. I @Lapp have never taken produced or sold methamphetamine. I do not personally condone the manufacture sale or consumption of methamphetamine. If you struggle with meth addiction please contact the American addiction center at 406-220-5357or get help on the web at https://www.samhsa.gov/find-help If you find yourself in any way replicating the process of meth production please contact your local police department so that they can assist you and get you the help that you need.

what is methamphetamine ?

Meth is a strong central nervous system stimulant that was discovered in 1893. Methamphetamine properly refers to the equal mix of levomethamphetamine and dextromethamphetamine in their pure amine forms though the most commonly known version of methamphetamine is the hydrochloride salt version commonly known as crystal meth. Methamphetamine was once readily available as an over the counter medication, the earliest prescriptions for it were for treating hay fever, asthma, and the common cold. During the second world war meth was given to soldiers to improve their performance. Factory workers and other laborers were also given methamphetamine to keep them awake and capable of working longer, it is during this time that the negative side effects of meth use started to be discovered. The first meth ban in the United States occurred in 1959 when meth based inhalers were regulated to stop abuse with them. Later in the 1970’s and 1980’s stricter restrictions pushed methamphetamine into being a schedule II substance. Despite its illegality meth manufacture has continued until today and due to many restrictions placed upon the process and materials meth manufacturing is a hard and dangerous process.

equipment

The manufacturing of meth requires at minimum the following materials:

Several round bottom flasks, a claisen adapter for the round bottom flasks, a still head that has a thermometer holder, Two condensers with straight central tubes one 35 cm long and the other 50 cm long, a vacuum adapter,a separator funnel, and multiple 24/40 size ground glass joints.You will need at least one each of the following round bottom flask: 3000 ml, 2000 ml and 500 ml; and two each of 1000 mi and 250 ml. I am not sure if changing the equipment type for a suitable replacement is possible or if the exact specifics really matter, I have never undergone these processes as they are illegal.

Due to the abuse of drug manufacturing most chemistry supply companies keep extensive records of customers and require an account to be set up before hand to purchase.

chemicals

The following are the necessary precursor chemicals:

Listed Precursor Chemicals:

-

Anthranilic acid and anthranilic acid salt

-

Benzyl cyanide

-

Ergonovine and ergonovine salt

-

Ergotamine and ergotamine salt

-

N-Ergotamine acid and N-Ergotamine salt

-

Norpseudoephedrine, norpseudoephedrine salt, norpseudoephedrine optical isomers, and norpseudoephedrine salts of optical isomers

-

Phenylacetic acid, phenylacetic esters (such as ethylphenylacetate) and phenylacetic salts

-

Phenylpropanolamine, phenylpropanolaminesalts, phenylpropanolamine optical isomers, and phenylpropanolamine salts of optical isomers

-

Piperidine and piperidine salts

-

Pseudoephedrine, pseudoephedrine salts, pseudoephedrine optical isomers, and Pseudoephedrine salts of optical isomers

-

3, 4-Methylenedioxyphenyl-2-propanone

-

Methylamine and methylamine salts

-

Ethylamine and ethylamine salts

-

D-lysergic acid, its salts, optical isomers, and salts of optical isomers

-

Propionic anhydride

-

lsosafrole

-

Safrole

-

Piperonal

-

N-Methylephedrine, its salts, optical isomers, and salts of optical isomers

-

N-Ethylephedrine, its salts, optical isomers, and salts of optical isomers

-

N-methylpseudoephedrine, its salts, optical isomers, and salts of optical isomers

-

N-ethylpseudoephedrine, its salts, optical isomers, and salts of optical isomers

-

57% Hydriotic acid

-

Ephedrine

-

Benzaldehyde

-

Nitroethane

-

GBH

-

Red Phosphorus; white or yellow Phosphorus

-

Hypophosphoric Acid, and its salts

-

lodine (must be over 2% tinticture)

-

N-phenethyl-4-piperidone

The following are necessary essential chemicals

list of essential chemicals:

-

Acetic anhydride

-

Acetone

-

Benzyl chloride (4 kg)

-

Ethyl ether

-

Potassium permanganate

-

2-Butanone

-

Toluene

-

Acetic anhydride

-

Benzyl chloride

-

Ethyl ether

-

Potassium permanganate

-

2-Butatone

-

Toluene

-

lodine

15.Acetone

process

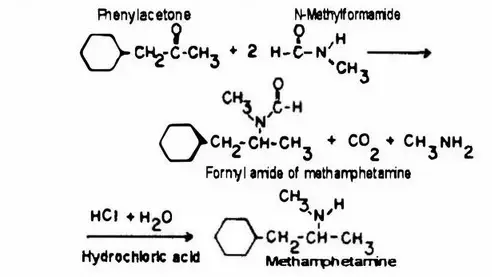

This is an example of the Leuckart-Wallach reaction. This reaction converts aldehydes or ketones to amines by reductive amination in the presence of heat. The Leuckart-Wallach can convert phenylacetone into meth. The process that will occur is shown in a diagram below:

the process of creating phenylacetone is shown in the diagram below:

the process of creating phenylacetone is shown in the diagram below:

the process of creating N-methylformamide is shown below:

the process of creating N-methylformamide is shown below:

To test the two productsi in a glass test tube there should be one part N-methylformamide for every two parts phenylacetone for the reaction, at this point simply putting them together in a test tube will cause them to mix together. The Leuckart-Wallach reaction method is highly sensitive and if not done right will create a red like tar substance instead of the desired methanphetamine, if a red tar like substance is created as a result of the N-methylformamide and phenylacetone reacting in the test tube then there was water present in the reaction and the process to create both chemicals must be restarted.

To test the two productsi in a glass test tube there should be one part N-methylformamide for every two parts phenylacetone for the reaction, at this point simply putting them together in a test tube will cause them to mix together. The Leuckart-Wallach reaction method is highly sensitive and if not done right will create a red like tar substance instead of the desired methanphetamine, if a red tar like substance is created as a result of the N-methylformamide and phenylacetone reacting in the test tube then there was water present in the reaction and the process to create both chemicals must be restarted.

If the red tar like substance is not created then the full reaction between the N-methylformamide and phenylacetone may proceed. For the full reaction there must be one part phenylacetonefor every 2.5 parts N-methylformamide. Though apparently the amount of N-methylformamide can vary from 2 parts to 3 parts and still be perfectly fine to react. The two chemicals should be mixed together in a 500ml round bottom flask, the flask should be set in a container filled 2/3 of the way with oil on a burner to apply even heat throughout the flask as the chemicals react. The oil may be vegetable oil or a subsitute oil which can similarly evenly distribute heat through the round bottom flask as desired. A metal pan is fine container for the oil as it will allow the contents of the glass round bottom flask to be seen. As heat is applied the contents of the flask should be stirred regularly with a thermometer. The temperature of the oil bath should be brought to 100° C over the course of 45 minutes or so. Once it reaches this temperatuee, the heat is turned back down so that the chemicals may stabilize at this point. Every degree of temperature must be closely monitored from this point forward. The temperature of the contents of the flask is heated up to 105° C. The chemicals in the flask must bestirred every 15 minutes. At about 105° C, the reaction will start, although sometimes the mixture’s temperature must go as high as 110° C before the reaction starts When the reaction starts, the contents of the flask begin to bubble. After the reaction starts the temperature must be lowered down to the initial heat that the mixture started to react at. It may be left at this state for several hours. Tap water flow is proper for use in the condenser. The heat should be turned on to the 500 ml flask, and a gentle rate of boiling is to be maintained for 2 hours. The mixture should turn black. The reaction going on here is methamphetamine formyl amide. his is a hydrolysis reaction. After the two hours have passed, the heat to the flask is turned off. While the flask is cooling down, 80 grams of sodium hydroxide and 250 ml of water are mixed in a 1000 ml round bottom flask. When both flasks have cooled down, the black reaction mixture is cautiously added to the sodium hydroxide solution. It is added in small portions, and then swirled around to mix it. They react together quite violently. The reaction here is sodium hydroxide reacting with hydrochloric acid to produce table salt, with formic acid to produce sodium formate, and with methamphetamine hydrochloride to produce methamphetamine free base. At this point the mixture must be distilled. The salt will form at the bottom of the flask and not react with the liquid substance within, After the mixture is distilled either toluene or ethyl can be used as the solvent to make the crystals in. With whatever solvent is used the insides of the condenser, vacuum adapter and 250 ml flask must be rinsed to get out the methamphetamine clinging to the glass. This rinse is poured in with the product. Solvent is added to each of the Erlenmeyer flasks until the volume of liquid is 300 ml. They are mixed by swirling. Then the sulfuric acid is then added to the solution and anair blower is started to slowly keep the fumes of dry HCI flowing into the meth free base rather than ever being sucked backwards.Within a minute of bubbling, white crystals begin to appear in the solution. to filter the crystals out. There should be a small amount of formic acid added as it acts as a catalyst. The formic acid should be buffered by the presence of free methylamine, to prevent the pH of the reaction mixture from falling too low and becoming acidic. The presence of water in the reaction mixture will cause the reaction to not happen. It prevents the phenylacetone from dissolving in the N-methylformamide, which creates low yields of purple-colored crystal. The filtering flask and Buchner funnel are set up now. The drain stem of the Buchner funnel must extend through the rubber stopper, because methamphetamine will dissolve rubber. A piece of filter paper must cover the flat bottom of the Buchner funnel. The vacuum is turned on and the hose attached to the vacuum nipple. Then the crystals are poured into the Buchner funnel. The solvent and the uncrystallized methamphetamine pass through the filter paper and the crystals stay in the Buchner funnel as a solid cake. About 15 ml of solvent is poured into the Erlenmeyer flask. The top of the flask must be covered and shaken to suspend the crystals left clinging to the sides. This is also poured into the Buchner funnel. Finally, another 15 ml of solvent is poured over the top of the filter cake.after this the vacuum hose is disconnected and the Buchner funnel. All of the filtered solvent is poured back into the Erlenmeyer flask it came from. It is returned to the HCI source for more bubbling. The Buchner funnel is put back into the top of the filtering flask. It still contains the filter cake of methamphetamine crystals. The vacuum shluld be turned back on, the vacuum hose must be attached to the filtering flask, and the top of the Buchner funnel is covered. The vacuum builds and removes most of the solvent from the filter cake. as the filtering process continues, one flask is being filtered while the other one is being bubbled with HCl. Solvent is added to the Erlenmeyer flask to keep their volumes at 300 ml. Eventually, after each flask has been bubbled for about seven times, no more crystal will come out and production process is finished.

Thank you for reading this far, please keep in mind that this process is illegal and that replicating any of it in part or in whole should not be done.

Kinda reminds me of uncle fester but newer.