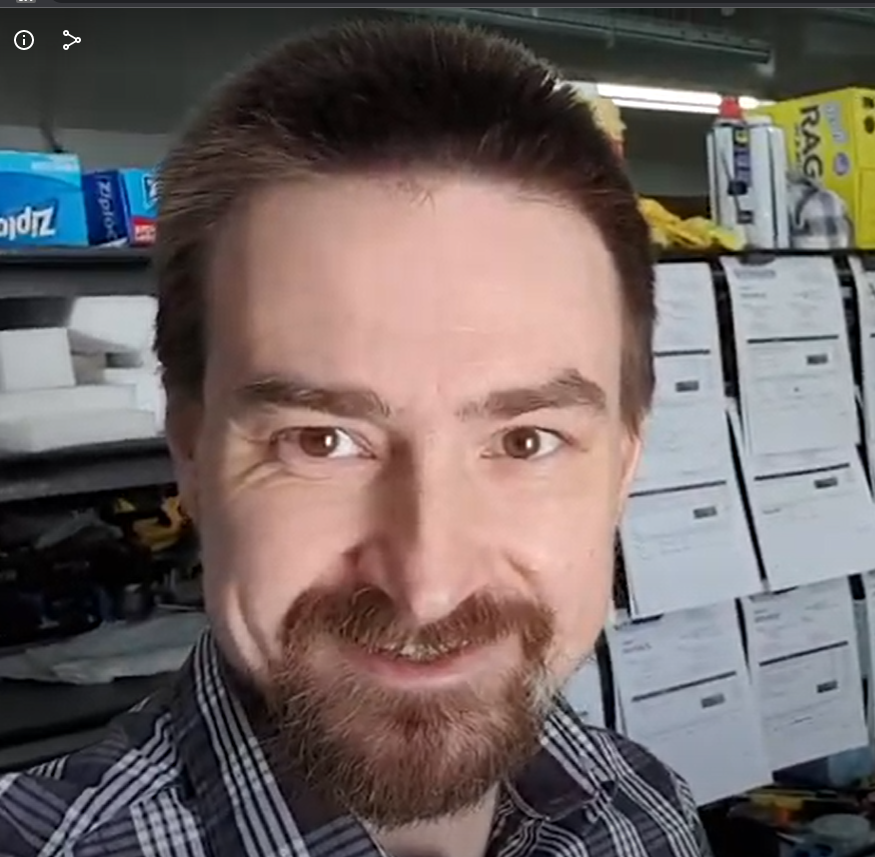

Instrument is a Geonics EM16 VLF receiver, using in the mineral exploration industry to find buried linear conductors.

Give it the vinegar and baking soda treatment.

I greatly prefer citric acid. It comes in crystals so a small tub equals gallons of vinegar, it doesn’t smell bad, and you can control the strength by dissolving more crystals into water.

It’s incredibly fast compared to vinegar at cleaning battery alkaline.

Citic or citRtic?

Citric. Fixed!

Cool, I thought there was a pretty good chance there are acids of which I’ve never heard.

Coca Cola works really well if you don’t have citric acid on hand. I’ve cleaned car battery terminals with it a bunch of times (over decades). The only bummer is that it’s sticky, but you can drink the leftovers.

To each his own. I’ve tried a few solutions. I use vinegar and apply it with some large cotton swabs. I usually wash them with the vinegar two or three times and let it sit for an hour. Then I use the baking soda dissolved into water and apply it several times. If possible to remove the contacts completely I will soak it in vinegar and then the baking soda solution. I buff the contacts if they are badly corroded. I can’t stress enough how much a little dielectric grease prevents further corrosion.

Yeah, I use baking soda and dielectric grease after acid too. I was only offering that citric acid is better than vinegar in every way.

and make a nice vinaigrette with it

I understand the vinegar, but why baking soda?

Neutralize the vinegar after dissolving the corrosion? I’ve not done that, but seems plausible.

It works. I’ve done it quite a few times. I have used a Dremel tool to buff the contacts and used a light coating of dielectric grease to prevent further corrosion.

A brush on the dremel?

Yes, wear gloves and eye protection. Those small wires would be a nightmare get out of your skin even more so for the eyes.

I would recommend rinsing the vinegar away with water instead. It’s already completely dissolved, but the baking powder might not be if you add that undissolved. You don’t want to leave anything behind.

Fizz

Volcano!

Abrasive maybe?

Jul 91? Now I feel old.

The instrument is fully analogue, designed in the late 70s. The serial number on the device implies it was manufactured in 87. I contacted the manufacturer and the last person who could service it has long since retired, but they sent me the calibration and tuning documents so I might be able to revive this beauty.

That’s actually awesome they sent you anything useful at all.

My brain kept tried to correct it to Jul 19…

I was still in junior school back then.

What you got there, is spicy salt. Get all that flavor and mix it with some eggs. The cat in the hat ain’t got shit on it!

Protip: once you dissolve as much of the gunk as possible, take a small metal brush and give the contacts a scrub. If they’re coated, this helps open up metal contact surface to give the new batteries a chance.

But if the contacts are too corroded, you may need to MacGyver something with a soldering iron.

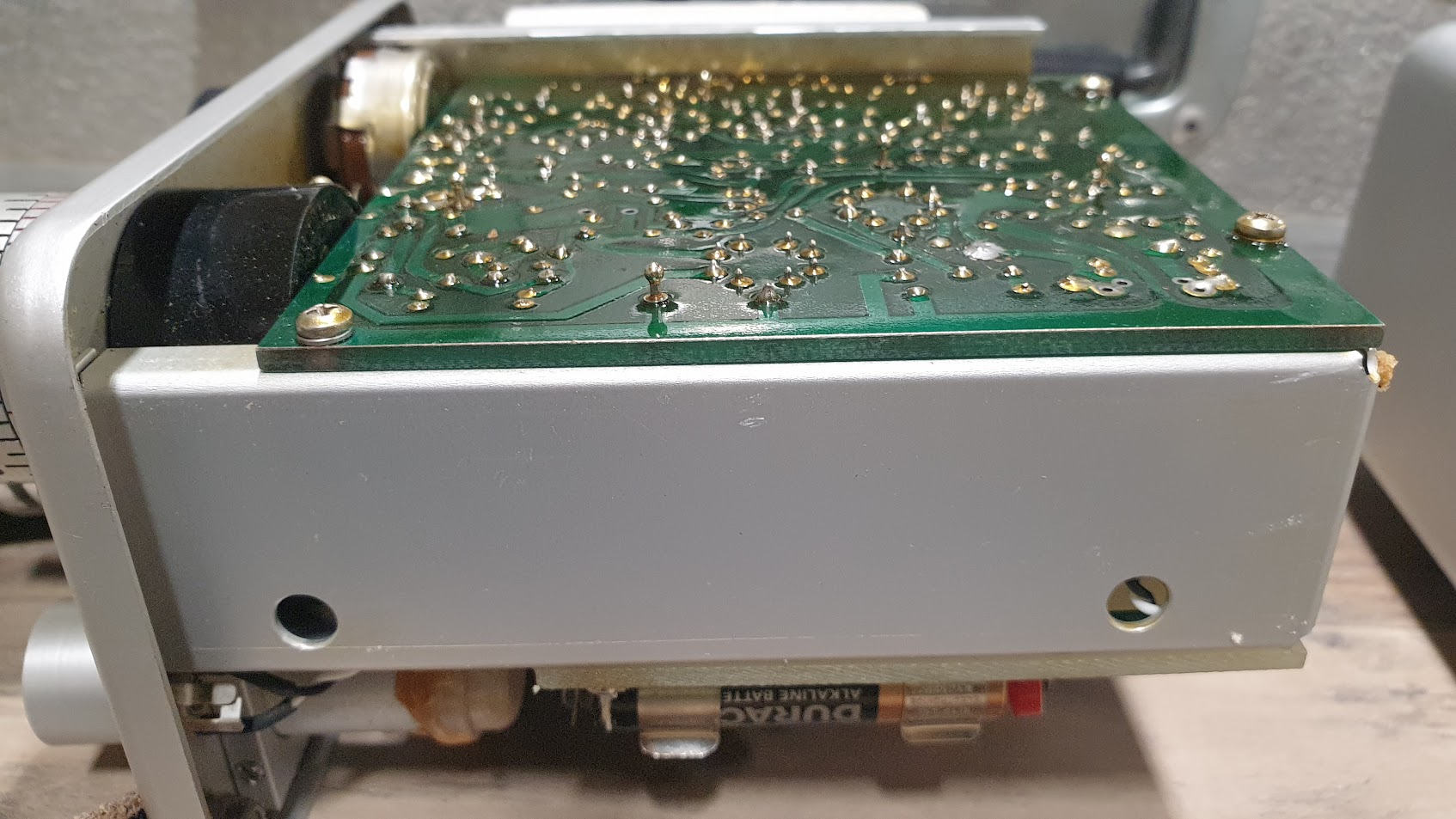

The whole battery mounting board is shot – entire traces corroded on it, and the contacts have effectively dissolved.

Fortunately, the machine was designed in 1977(ish) and batteries have gotten a lot better since. 6x AA batteries can now be replaced by a single modern 9V and it’ll deliver enough current. So I’ll mount a new 9V holder and solder it into the battery board wiring harness. I’ve already tested that solution on the breadboard and the machine appears to work.

9V batteries existed in the seventies. They just have far less capacity than six AA cells.

I agree. However the Ah capacity of a modern 9V is pretty good compared to the 70s. Unless you buy the cheapest 9V crap you can find ;)

If I remember it correctly, it’s not just the overall capacity but also the how much the voltage drops as the current being drawn goes up (i.e. their internal resistance).

You can pull several Amps out of an AA without its voltage dropping significativelly though it does accelerate depletion quite a lot if you do it in a sustained way (the volage curve of alkaline batteries actually depends on how much current you draw so if you just draw at say 100mA the “knee” in the curve were the voltage drops down from around 1.5V to a value too low to be useful is a lot sharper whilst if you draw 1A it’s a lot softer with the voltage starting to sinking much sooner for the same fraction of total charge drawn).

Or in other words, the 9V battery might no be able supply enough peak current whilst still remaining close enough to 9V.

(It was actually quite a commonly reported problem in Arduino forums that people used 9V batteries for things like motors and then had weird power drops or the motors didn’t actually work as expected even though theoretically everything seems to be in spec for them)

You should probably test the device under “in use” conditions with a 9V battery rather than just in standby before you replace the current setup with a single 9V battery.

I appreciate your caveat about peak load. Fortunately for this device it is largely irrelevant. It’s so old school and analogue that there isn’t a standby draw – it’s either on or off. Its operational time is measured in days on a single 9V.

It might be interesting, so I’ll describe the instrument. Starting with some VLF background:

There are a number of VLF stations scattered around the world – for example station id NAA in Culter, Maine (24.0kHz) – used to communicate with their submarines while submerged. If they only transmitted when they had something interesting to say to the subs, that would be useful information to an enemy. So they have to transmit continuously (except for on scheduled maintenance days for the transmitters). These are very powerful huge antennas, often spanning entire valleys – after all, the wavelength at 24kHz is enormous. Different stations have different frequencies and we know about most of them.

At a sufficient distance away from these antennas, all incoming signals are polarized due to reflecting off the ionosphere. These radio waves pass over linear conductors in the ground which will distort the polarization. What we’re effectively measuring is the distortions in these incoming radio waves to map the locations (and orientations) of linear conductors (natural antennas) in the ground, up to about 250m below surface.

So this device is used to measure the incoming signal direction and polarization. It does so by setting up a harmonic oscillation on the device and emitting a tone. There’s a couple of magnetic coils on the device, and as you swing the device about, the received signal from the transmitter and the onboard oscillator will constructively or destructively interfere, changing the tone. You note the direction the tone is the strongest using a compass and inclinometer (both analogue) and write it down in a notebook. Then move to your next position and repeat.

Prospectors have been using this for five decades at least.

But as you can see, not a complicated thing from an electronics perspective. The only complicated thing is tuning the on-board oscillator properly.

Yeah, that’s quite a shrewd way of going about it.

Since it’s not emitting anything the power it needs will be way less that something emitting its own signal and then checking for bounces which is how I naveivelly expected it would work.

Cheers for the detailed explanation.

I have a running list where I have been collecting words that I like for the last few years.

“Shrewd” is a good word and it’s going on my list. Thank you for the contribution.

please advise how to dissolve the gunk at home (using household items, cleaning products, or something that is available at local stores).

Someone said “use acid”, but I’m like “how the F am I supposed to get acid?”

Vinegar is acetic acid. Distilled Vinegar is quite useful as a general household cleaner.

Lemon juice contains citric acid.

CLR or a similar product that takes care of limescale (etc) is a mixture of acids.

Muriatic (another name for hydrochloric) acid is available from most hardware stores and can be used for dealing with rust.

Mild acids that are food grade are great because you don’t have to worry about occupational health exposure. A lot of people use vinegar. I use citric acid – which you can find in the grocery store in the spices section. Citric acid is what makes sour candies sour. You buy it as a powder.

I mix a little water and citric acid and let the part soak in it, then brush with a soft wire brush (not steel wire, as it’s too hard and will scratch the parts too much).

But, as a tangent, buying stronger acids is pretty easy, depending on the acid. Hydrochloric acid is sold in hardware stores as muriatic acid. Sulphuric acid is used to recharge lead-acid batteries. You’ll have a harder time finding nitric acid (because people can make explosives with it) or hydrofluoric acid (cause it is actually deadly as fuck), but industrial suppliers often have them. I wouldn’t handle any of these without some training. Even muriatic acid will off-gas chlorine and cause all the tools in your shop to rust if stored improperly. (From experience.)

Lots of good suggestions already, but you could also try oxalic acid aka Barkeeps Friend. It’s pretty mild and works wonders on metals.

I use citric acid on a lot of connectors when the pins are corroded (for the same reason). Revived a lot of cables that way. Good advice :)

Puts you at ease to know those batteries are good for another 67 years

I would personally scrape the gunk as much as possible, remove the contact pads and resolder new ones.

Looks like you’ve got a computronium infection. That’s getting more and more common these days.

Just hit it with some vinegar or windex. If those don’t work, you may have to just toss it out.

Hey I just remembered thirty years ago I worked at a car dealership. Anyway you could pay extra for all the chrome emblems to be gold plated. It’s cheap and easy to do. You etch the chrome with acid. Then i think there was some sort of rapid electroplating process to deposit the gold layer from a solution.

Your thingy has already been acid etched and gold is an excellent conductor! I wouldn’t use this method unless you knew someone that has the kit, or you were thinking about it as a hobby anyway.

Fun Fact: batteries only do this when they’re over-discharged. If you design your circuit right, this won’t happen.These batteries are in a circuit which has a physical power switch separating it from the device, meaning there should be zero parasitic drain while off.

Thus I conclude your fun fact to be apocryphal.

Guess the Duracell rep lied to us. Sorry.

Duracell rep might be a sales robot. Or possibly talking about another type of battery? Anyway, points for learning :)

Then why have I had Duracells leak in an unopened package before the expiration date?

I hate Duracell for this reason. Thank god we finally got decent rechargeables.

Duracell suck but Kirkland are so much worse. Rechargeable Eneloops are the way to go.

That doesn’t make sense. Every alkaline cell suffers from this due to the formation of hydrogen gas inside the cell over its lifespan, as well as corrison caused by the chemistry of the cells themselves. It’s not specifically driven by the charge of the cell; although that is certainly a contributing factor and poorly designed circuits will exhibit more wear on the cell causing more rapid corrison & gas formation.

The leakage scenarios for alkaline cells never seem to make sense.

https://www.eevblog.com/forum/blog/eevblog-1508-we-finally-got-alkaline-battery-leakage!/