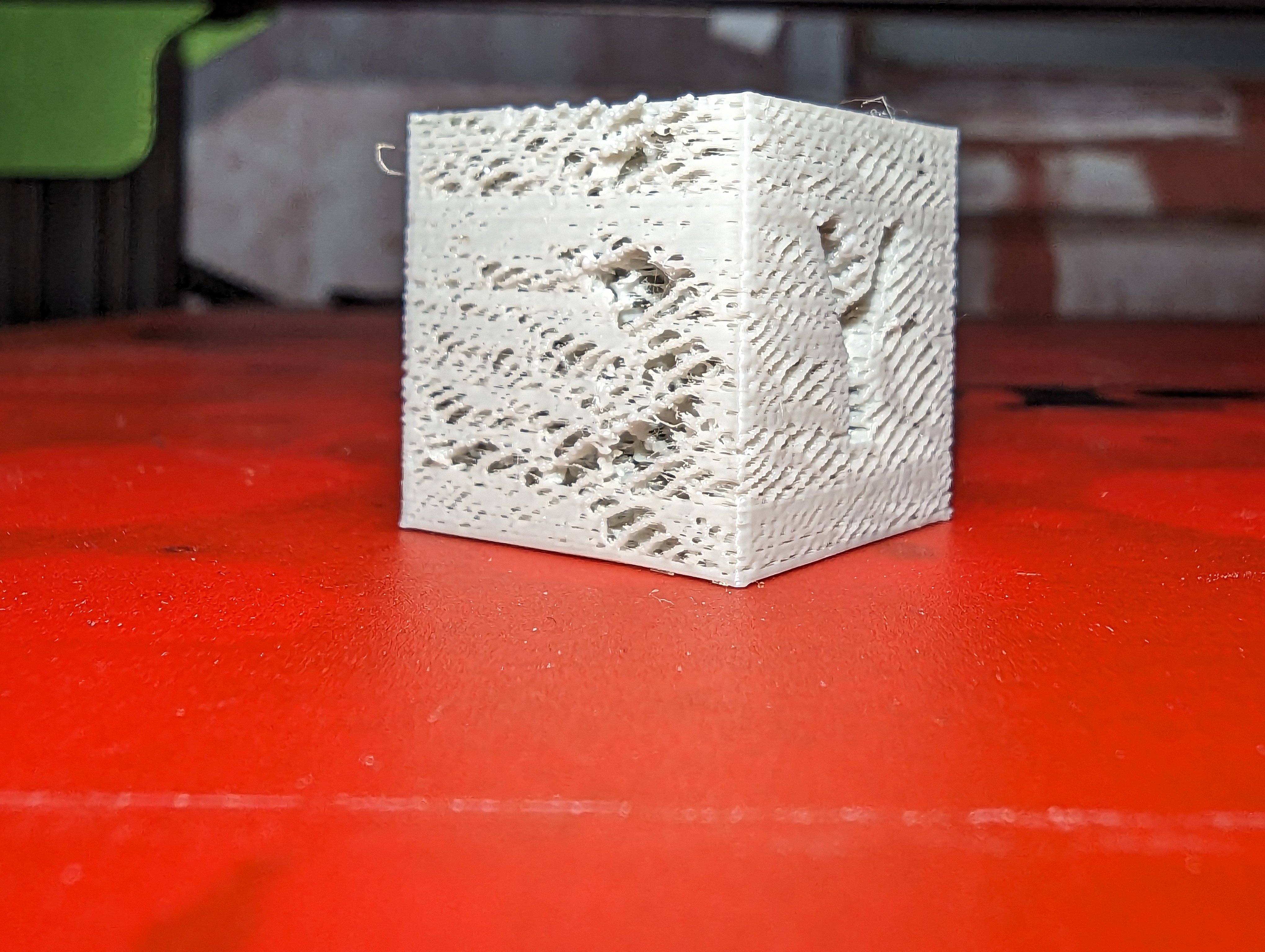

Hi everyone, I’m extremely new to 3d printing, and have taken over a printer from a friend who doesn’t use his. I’m trying to get those smooth prints I see people having, and I understand I need to get a smaller layer height to achieve the details. However my stuff keeps coming out looking like the pictures below.

Any idea what’s going on and how I can start fixing it?

I’m printing PLA filament.

- Nozzle temp: 215

- bed temp:70

- nozzle size: 0.3mm

- Layer height: 0.1mm

Thank you!

There are multiple potential issues. It is hard to say where to start. The little solid band in the bottom pic, below the X, hints at an issue with an obstruction in the nozzle.

The repetition in the outer wall pattern hints at an issue with the extruder gears. Any time you see a pattern like this, it relates to the extruder mechanics. This could be any number of issues like too much or too little tension on the filament at the extruder feed gear. It could be cracked or worn out parts. It could be a worn out or bad gear or idler. The actual extruder mechanism is a high precision ~0.01mm class system. Any error here is a big problem.

It looks like you just placed these on a print bed for pictures. If these are how they were printed, your first layer height is too high. Maybe it is just the lighting, but if the top is more sparse than the rest of the print, I think you need to calibrate your flow rate steps per millimeter.

Thanks! Would you have any general advice on how to check or fix the extruder?

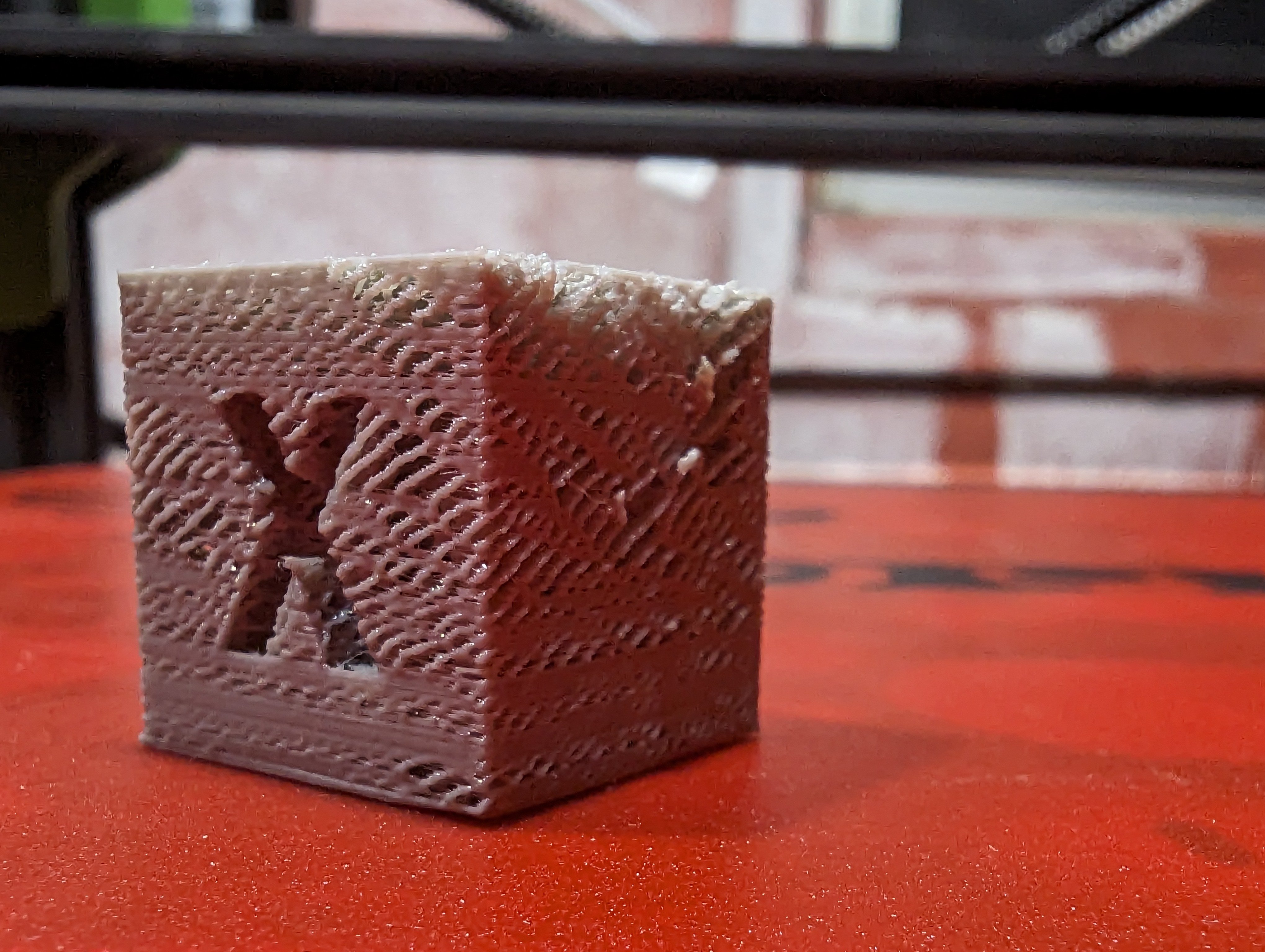

I did just place them on the bed after plucking them out. Sorry for the bad pictures, I’m no good at taking them haha. Here’s what print looks like before I pluck it off the bed:

I realise there is a lot of stringing going on, but I’m not sure how to fix it. Online says I need to adjust retraction settings, and I’m still messing around with that. I’ve currently got retraction distance at 8.5mm and retraction speed at 40.0mm/s.

Are these holes also caused potentally by bad extruder gears?

Thanks for the help, I really appreciate it! I’m trying to fix up an old printer that my friend doesn’t want anymore, and it’s my first 3D printer, so there’s a lot of basics I don’t know.

I bet your temp is way too high and causing the stringing. 8.5mm retraction seems pretty excessive as well so try reducing your temp and retraction settings. I personally print PLA at 195 and I believe Bowden extruders should be around 4-6mm retraction (don’t quote me on this. I have a direct drive extruder). You can print out a temperature tower that’ll increase the temps every few layers so that you can see which one gives the best results. After this you can do a stringing test print to see if there’s an improvement.

I don’t have any direct experience with a Bowden extruder so I’m no help for retraction in this context. You’ve got compounding issues here, and I don’t think any one solution is going to “fix” it.

In general, stringing is a temperature issue. Lowering temp will reduce stringing in most instances. On a Bowden system, the extra gap between the Bowden tube and filament inside allows the filament to hold load tension like a compressed spring. On a direct drive extruder there is not very much space for the filament to hold loaded tension. So when the extruder retracts a small amount, most of the pressure on the melt zone is relieved. If the temperature of the melt zone is high, the gravity of the melted material that is still present can ooze out of the tip. When the print head is traveling, this ooze can catch on a passing print feature and anchor itself. This is where strings come from. If retraction is not a factor, by reducing the temperature, the melt zone is less viscous, and thus less likely to ooze enough to create a string.

With a Bowden setup, the tension in the Bowden tube needs to be accounted for too. It takes a lot more retraction to relieve pressure on the melt zone. This needs to happen very fast too. When the print extrusion is terminated before a travel move, there is a very small motion to anchor and control the termination. The retraction needs to happen during this motion or it will likely make large strings. I’m afraid you may have a circumstance like this based upon how large your strings are and how there are so many gaps in the print. This is something I only know about through inference of another situation I have encountered.

PETG has a problem with moisture that causes oozing and stringing. There are a bunch of different problems this creates, but one of them is a type of stringing that is kinda similar to what your print looks like. I’m very hesitant to say this IS the main problem though. With PETG it is super sticky when it is molten, more than any other filament. Moisture, even a tiny amount, sitting in the melt zone during a travel move, will expand just enough to cause the filament to anchor to almost anything. For most other filaments, a string is usually just some insignificant wisp that has very little volume of material compared to the stuff in the melt zone. With PETG the ooze string anchor tends to pull out a significant amount of material from the melt zone. This tends to make problems for the start of the next extrusion when there is not as much material as the g-code needs to anchor the beginning of an extrusion. It also affects the termination that comes back to the same seam. This is the cause of most problems with PETG prints.

PLA does not have issues like this in general. It is sensitive to moisture and this can cause stringing, but it is not anywhere near as sticky when molten. The problems are therefore far less of a PITA to deal with.

I only share this so that maybe you get an idea of the dynamics involved here. The critical thing you’re messing with is what is happening inside the melt zone and all of the factors that could affect the molten material. The g-code is blind. It can’t account for any in situ circumstances. It follows instructions exactly and assumes they execute correctly every time.

My other concerns are that your steps per millimeter, your PID tuning values/calibration of your hotend, the potential for a clog in the nozzle, and the potential that you are printing at too high of a temperature.

I don’t use Cura much, so I’m no help really on that front. I use a combo of Prusa Slicer and Super Slicer. The calibration tools built into Super Slicer are really helpful for me because they contain all of the info I need to read along with the setup to do each calibration in one click. It is also setup to calibrate your actual profiles directly in a way that seamlessly integrates back into whatever project you’re working on. (It is FOSS too). If you are already comfortable with Cura and using it, check out the CHEP channel on YT. He has a bunch of tutorials on setting up project level printers like enders really well and might be more help, especially with the Bowden stuff.

Underextrusion. You probably have burnt filament clogging your nozzle. Get your nozzle to 80C, then set it to 150C and start pulling the filament back out as the temperature climbs. It’s called a cold pull and usually clears this sort of thing.

Set your initial builtplate temp to 70, and the builtplate temp to 55 for printing. At 70 the pla will hit glass transition, then when it cools to 55 the adherence will be very good.

If you want smooth walls, slow the speed to like 40mmps, and squish the layers down to 0.10 mm with a .4mm nozzle if you can.

Play with ironing for the top surface smoothing.

I don’t recommend reducing your cooling much with pla. Maybe down to like 50% at the lowest.

Edit: your nozzle and later height should be fine, I glossed over that. Bring the nozzle down to 200 or so.

To add to this, I would highly recommend not worrying about using a .10mm layer height until you have reliable prints at .20mm height.

Trying to get finer detail is just compounding issues onto a print that looks to have quite a few things wrong.

I agree with you on underextruding. Easiest way to test would be for OP to measure 150mm of filament from the entrance of the extruder and mark it. Set nozzle temp to 215 or so, and manually extrude 100mm. Then re-measure to your mark and see how far off you are. If it’s way off OP needs to calibrate his extruder motor steps.

Also as other people have said, might be worth trying a different filament, especially if that filament is really old.

A couple things if you’re new-ish:

First, I would highly recommend using a 0.4 nozzle. That’s the standard size most people will assume you’re using and it will just make your life easier.

Second, start with a 0.2mm layer height and adjust down in steps of 0.04. Below 0.12mm can bring in more compounding problems related to the filament itself.In short, tune for the defaults first, then adjust.

It might just be sliced for a 0.4 nozzle (default). If you downloaded the gcode file, that’s probably it. Run the stl or 3mf through your slicer software, making sure the extruder size is 0.3mm.

For some reason, I’m having trouble getting a sense of the depth of those strands and holes. If you hold it, does the surface feel scratchy and rough, or bumpy and smooth?

What adjustment have you made to the machine? Did you recently change to that 0.3mm nozzle?

Are you sure it’s PLA and not other flavor, like PLA Pro, PLA+, etc.?I am pretty new to fdm, but is it possible that you are using a high temperature and low cooling? Another possibility is the filament is too wet and need to be dried. Thinking about it, wet filament is a higher possibility.

Also you can try increasing the flow rate or if it’s not possible slowing the speed. It may be under extruding.

Have you done a test print while watching it and listening?

It looks like under extrusion but it’s hard to say if it’s an obstruction, poor gear contact, or steps.

I would watch and listen to a print for a while and see if it’s making any clicking or snapping sounds. That could be a good indicator of something wrong with the extruding part.

Thanks for the advice! I tried listening to it, but I haven’t heard anything strange (I think). There’s no clicking sounds or snapping sounds, just the whir of the motors. My PSU fan is making a clicking noise, but I think it’s because it’s spoiling, I might replace it soon.

Alright so first big thing, if you’re using Cura make sure it’s set to a filament diameter of 1.75mm. If memory serves it still defaults to 3mm.

That can cause serious under extrusion problems that you’ll be chasing forever until it’s fixed.

Also what speed are you printing at, what printer are you using, and what slicer?

Thank you for the reply!

I’m using an old Tevo Tornado (gotten from a friend), printing at 60mm/s, and Cura 5.4.0.

I’ve checked to make sure that the filament diameter is 1.75mm.

I seem to have gotten better results after reducing the speed to about 30mm/s, and increasing the temperature to about 215c - 220c. I understand 220 is a bit too hot? But I assumed that my filament was causing some issues, because printing at 215 seemed to have the same issue.